26 Apr Tensile Tests

FEA-Solutions (UK) Ltd delivers accurate stress analysis results. This requires that all input data is accurate as well, including the mechanical properties of the materials used in your design.

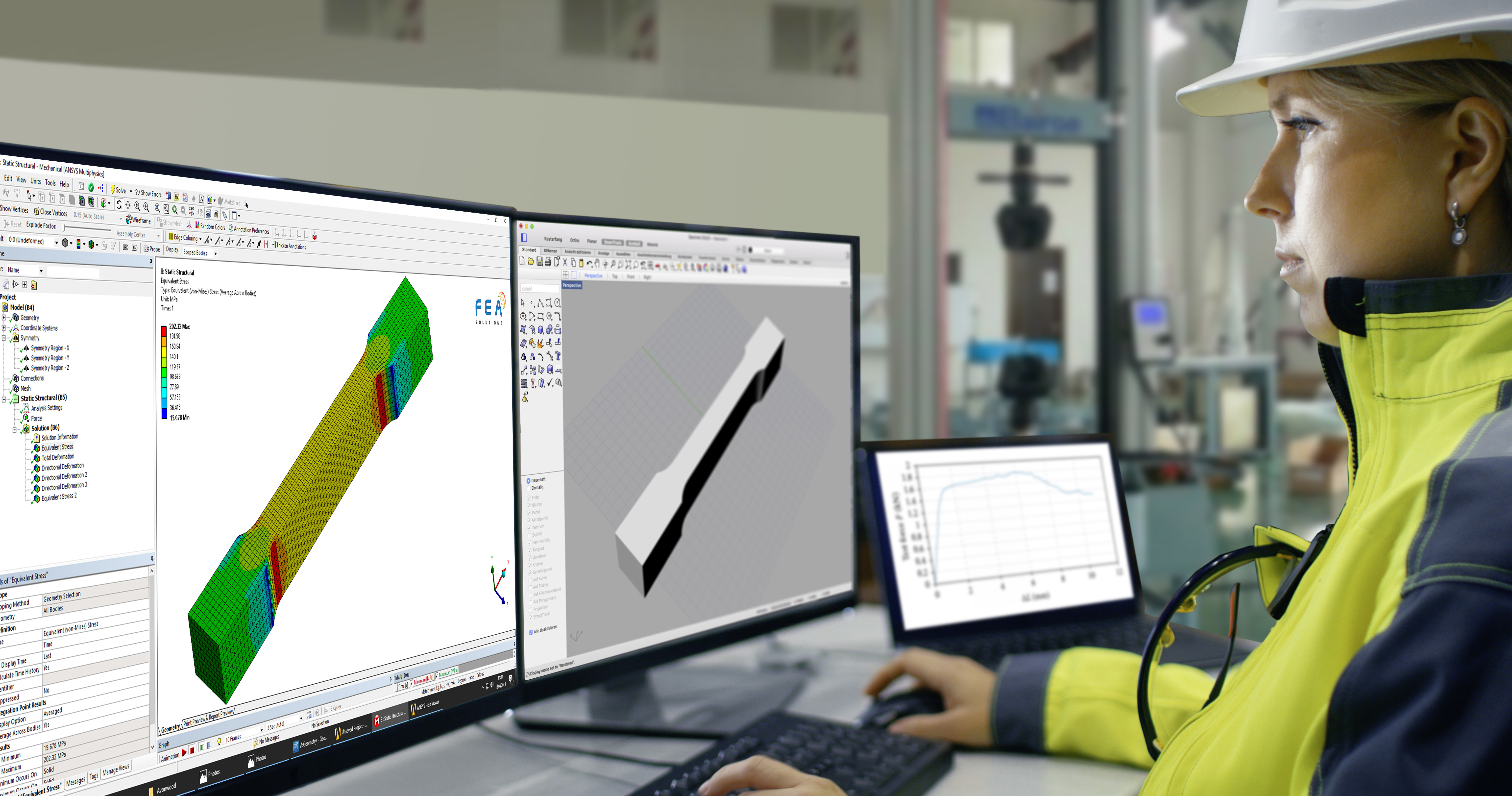

Mechanical properties are usually established by performing specimen tests. Most commonly used, in particular for metals, are uniaxial (that means load in one direction) tensile tests. For this test, a specimen, usually with a rectangular cross section, is machined. The specimen is then fitted to a specialised tensile test machine. There it is subjected to a tensile load that is slowly increased until the specimen breaks. During the test, the length increase (elongation) of the specimen and the tensile force are recorded. The test results can then be plotted in a graph.

Several tests with specimens from the same material batch are performed to allow a statistical evaluation of the results.

There are many other test methods used to determine the various mechanical properties of a material. What they have in common is that they are usually uniaxial.

Please call us today on 01202 798991 to discuss how your project can benefit from our accurate FEA results.