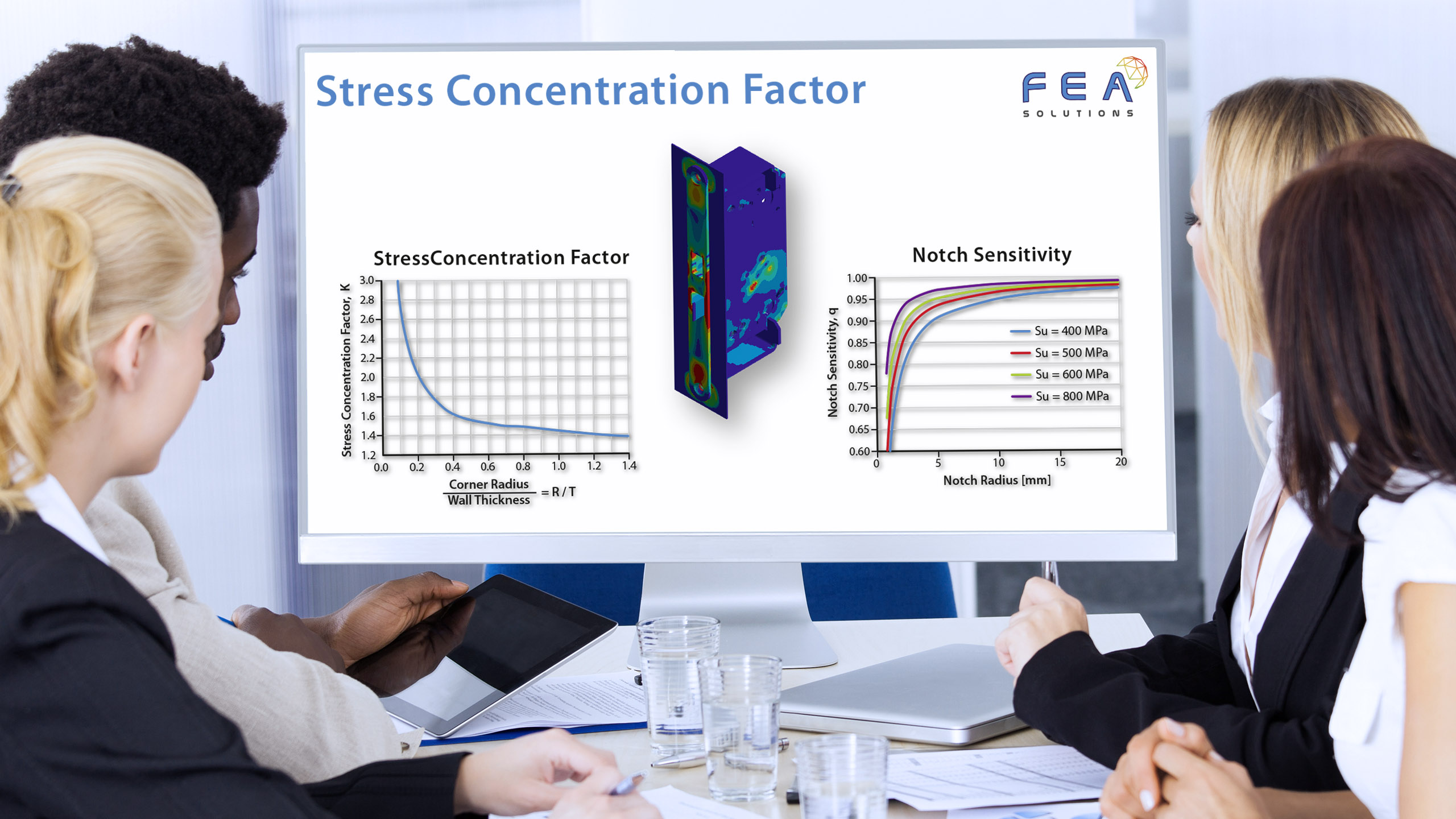

21 Sep Stress Concentration Factor

Besides the surface factor (https://fea-solutions.co.uk/surface-factor/), the stress concentration factor or notch sensitivity is another key modification that could reduce the endurance limit.

The stress concentration factor is used to account for the effect of irregularities or discontinuities such as holes, grooves or notches that are not represented in detail in the FEA model. Were they modelled in detail, the stresses would increase dramatically in such regions. The factor is calculated as the ratio of the highest stress in the notch to a nominal stress of the cross section without a notch.

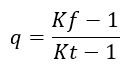

The approximation of the effect of a notch or hole of a given size or shape on the endurance limit of the material is captured by the following equation (notch sensitivity is q):

Kf is the fatigue notch factor, which is the ratio of the maximum stress in a notched specimen to the stress in a notch free specimen and it is dependent on the geometry of the notch, and Kt is the stress concentration factor.

From this relationship, a couple of observations can be made:

– If q is 0, then the notch factor is 1, and the material has no sensitivity to notches at all.

– If q is 1, then the notch factor and stress concentration factor are equal, and the material has full notch sensitivity.

It must be noted that when conducting a fatigue analysis (https://fea-solutions.co.uk/fatigue-analysis/) in FEA software where all small geometric details are modelled with a good quality mesh (https://fea-solutions.co.uk/mesh-refinement/), applying the stress concentration factor is not required as the FEA already considers any geometric discontinuities that may affect the endurance limit.

Please call us today on +44 (0)1202 798991 for any engineering analysis requirements you might have.