28 Apr Stress Averaging

Stresses of a FE analysis are calculated for elements at their integration points (https://fea-solutions.co.uk/nodal-stress-calculation/). To come up with a nodal stress, the common procedure is to calculate the average of the extrapolated element stresses at that node.

There are two methods for stress averaging:

– Topological method

– Geometric method

The topological method averages the stresses at a node due to the contribution of the elements that share it, but it does not include the effect of the element size on the averaged stress, whereas the geometric method does account for the effect of the element size on the averaged stress.

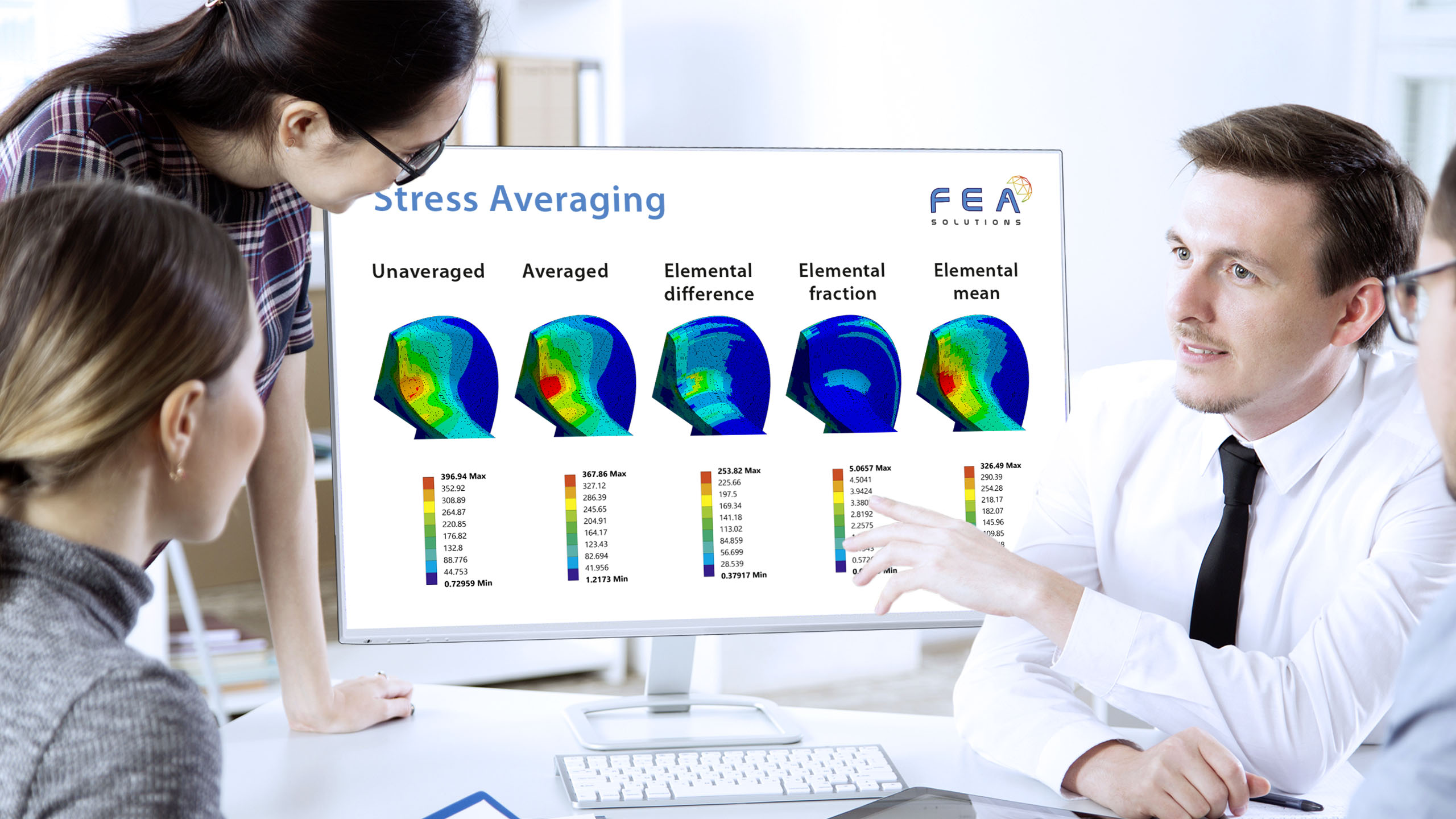

Comparing the averaged and unaveraged stress results is a good indicator of mesh quality. If the unaveraged stress results are greatly different from the averaged stress results, the mesh is too coarse and needs to be refined.

Nodal displacement results are precise. Nodal stress results can be accurate, depending on the mesh size, but they are never precise. This is true for solid elements (https://fea-solutions.co.uk/solid-elements/), partly true for plate elements (https://fea-solutions.co.uk/surface-elements/) but not applicable to beam elements (https://fea-solutions.co.uk/line-elements/).

As well as showing averaged and unaveraged nodal stress results, other quantities can be shown, if more insight to the mesh quality is required:

– Elemental mean stress

– Elemental difference stress

– Elemental fraction stress

Call us today on +44 (0)1202 798991 to discuss any engineering analysis requirements you might have.