17 Aug Fatigue Analysis

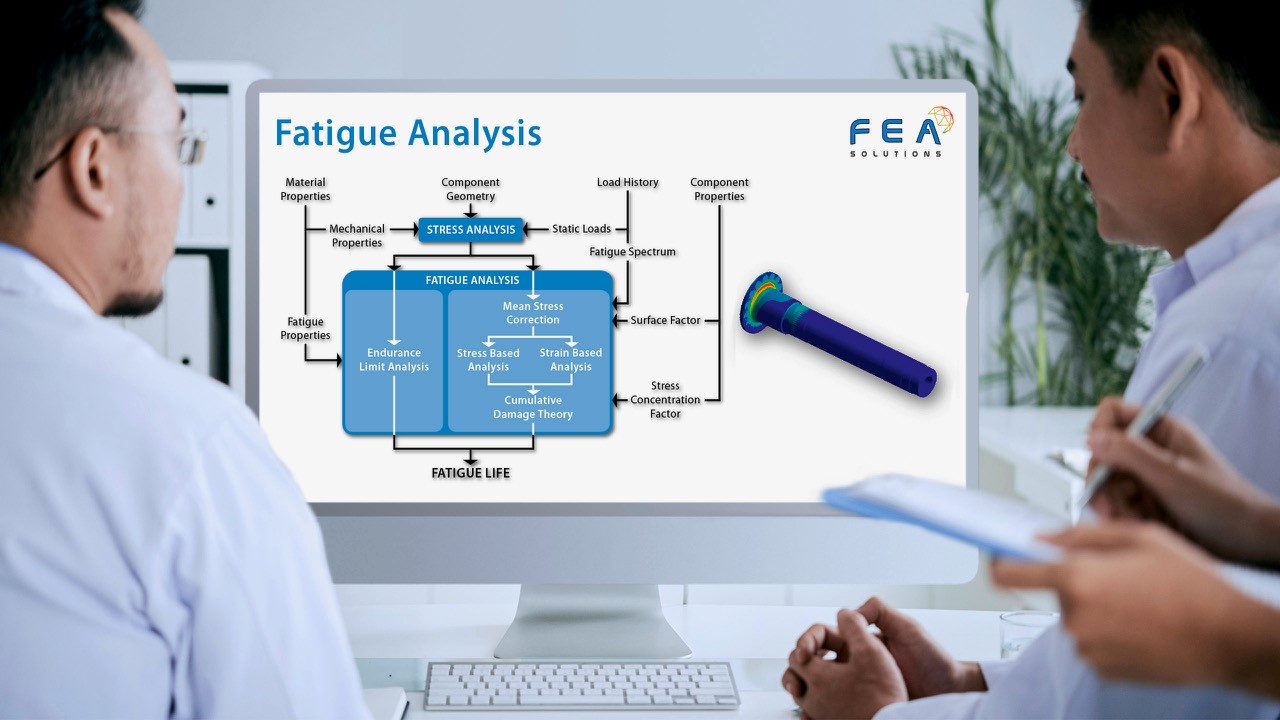

A fatigue analysis is performed to calculate whether a structure will fail after a certain number of repeated loading and unloading, so-called load cycles, rather than after one load cycle as simulated in a static analysis. The fatigue failure is due to initiation and propagation of a crack somewhere in the component.

The pre-requisite for a fatigue analysis is always a stress analysis. This can be either a static stress analysis (https://fea-solutions.co.uk/static-vs-dynamic-analysis/), which will result in a single peak stress, or a Random Vibration Analysis (RVA) (https://fea-solutions.co.uk/random-vibration-analysis/), which will result in a number of peak stresses. If a RVA is carried out, the stresses must be reduced to a single stress value for the fatigue analysis to take place.

There are three types of fatigue analysis:

– Endurance limit analysis – the simplest of fatigue analyses.

– Stress based fatigue analysis – does not differentiate between crack initiation and propagation.

– Strain based fatigue analysis – concerns itself only with crack initiation.

Because FEA stress results are multiaxial but experimental fatigue data is usually uniaxial, the stress must be converted from a multiaxial state to a uniaxial one. One of the following stress values can be used:

– Maximum Principal stress,

– Absolute Maximum Principal stress,

– Component stresses,

– Von Mises stress,

– Signed von Mises stress.

The Maximum Principal stress is most commonly used. However, it is prudent to re-run the fatigue analysis with the other values to see which is the worst case.

Fatigue analysis does not take into account how fast loads are applied or how long they remain applied. It only looks at the number of cycles. However, in reality a very fast load application might have a different effect on the structure than a slow one (https://fea-solutions.co.uk/criteria-for-dynamic-analyses/).

There is a very coarse rule of thumb for fatigue: Reducing the peak stress by 10% will increase the fatigue life by a factor of 2. To have a high fatigue life, it is most important to reduce peak stresses, in particular those with a high stress gradient. Furthermore, tensile stresses are more likely to cause fatigue failure than compressive stresses.

Please call us today on +44 (0)1202 798991 for any engineering analysis requirements you might have.