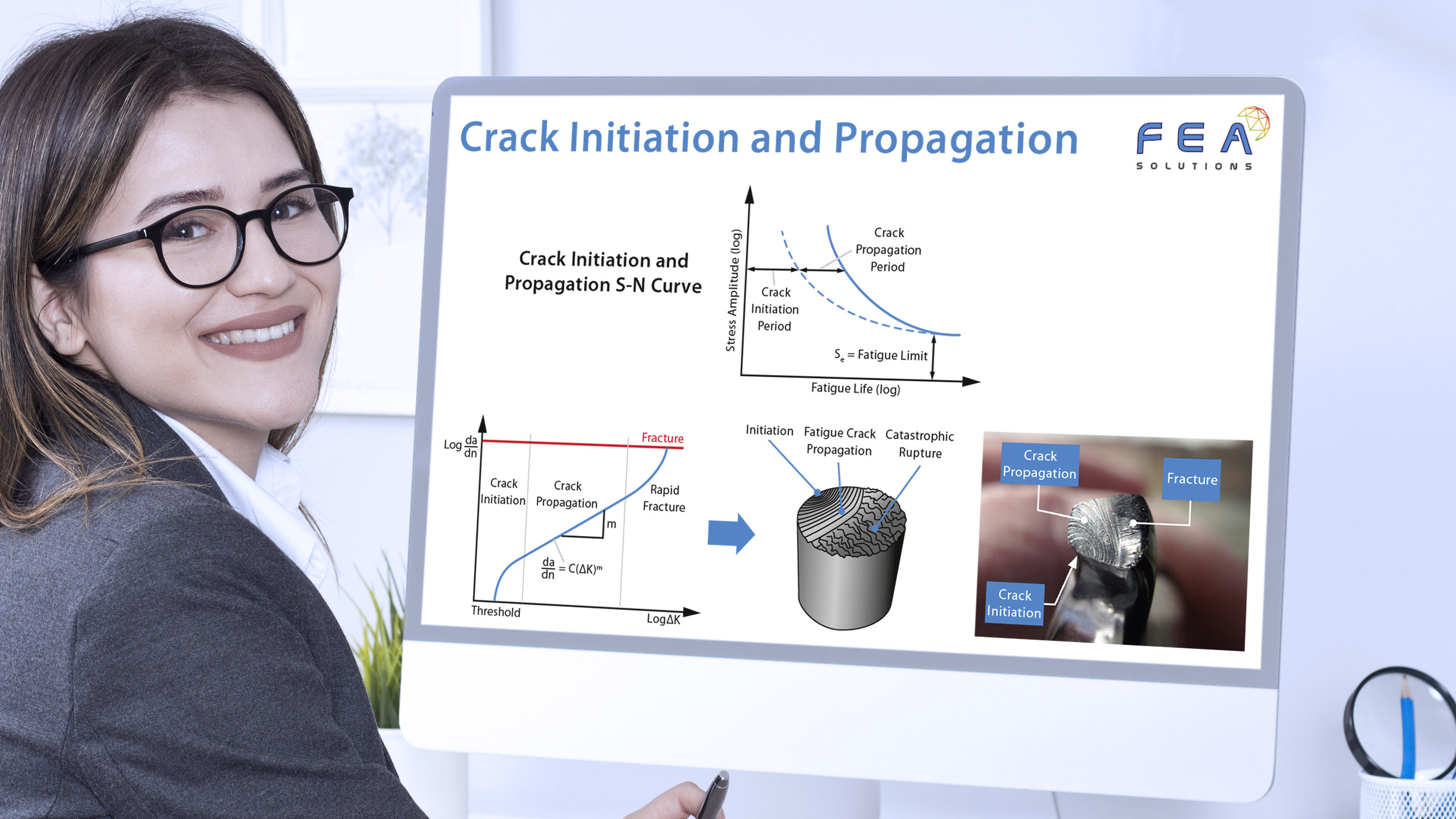

16 Nov Crack Initiation and Propagation

The three stages of fatigue failure in a component are: Crack Initiation Crack Propagation Rapid Fracture Crack initiation, sometimes called crack formation, occurs in areas of concentrated stress on the surface of a component, and in areas where surface defects can be found. As surface defects...